Nozzle, Air, Power, and Abrasive Requirements

– View Instructional Guide (PDF)

Blasting Industry Terms

A quick overview of blasting terms you should be familiar with or which are commonly misunderstood.

– View Instructional Guide (PDF)

How It Works: C-Series 3.6/6.0 CU FT Pressure Release (CPR) Systems

This section of the manual is designed to give you a general understanding of how our Abrasive Blasters function. All sections of this manual must be read and understood before operating equipment.

– View Instructional Guide (PDF)

How It Works:

Zero Suction Cabinets

Suction blast systems work by drawing abrasive media to the nozzle using suction instead of pushing it through a blast hose with compressed air.

– View Instructional Guide (PDF)

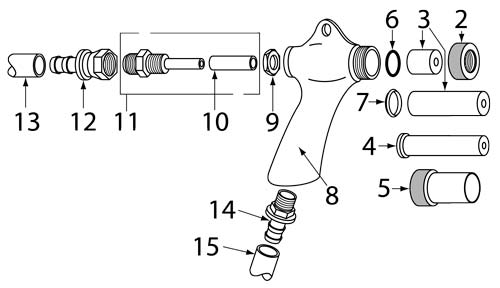

Blast Hose Coupling / Nozzle Holder Installation

Installation Instructions

– View Instructional Guide (PDF)

Siphon Blast vs Direct Pressure Air Consumption

| Siphon Blast Cabinet CFM Consumption | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Size | Air Nozzle Orifice | 30 PSI | 40 PSI | 50 PSI | 60 PSI | 70 PSI | 80 PSI | 90 PSI | 100 PSI | 120 PSI |

| 1/8” (#2) | 1/16” | 2.45 | 3 | 3.55 | 4.1 | 4.65 | 5.2 | 5.74 | 6.7 | 7.6 |

| 3/16” (#3) | 3/32” | 5.52 | 6.79 | 8 | 9.22 | 10.48 | 11.68 | 12.9 | 14.4 | 17.1 |

| 1/4″ (#4) | 7/64” | 7.66 | 9.41 | 11.13 | 12.8 | 14.55 | 16.2 | 17.94 | 19.65 | 25 |

| 1/4″ (#4), 5/16” (#5) | 1/8” | 9.8 | 12.03 | 14.26 | 16.39 | 18.62 | 20.76 | 22.99 | 25 | 30 |

| 5/16” (#5), 3/8” (#6) | 5/32” | 15.31 | 18.8 | 22.28 | 25.61 | 29.09 | 32.43 | 35.92 | 40 | 49 |

| 3/8” (#6) | 3/16” | 22.11 | 27.16 | 32.01 | 36.86 | 41.9 | 46.85 | 51.6 | 56 | 66 |

| 7/16″ (#7) | 7/32” | 31 | 38 | 45 | 52 | 59 | 66 | 73 | 80 | 90 |

| 1/2″ (#8) | 1/4″ | 39.28 | 48.11 | 56.84 | 65.57 | 74.4 | 83.13 | 91.95 | 102 | 120 |

| Direct Pressure Blasting CFM Consumption | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nozzle Size | Nozzle Size (Decimal) | 20 PSI | 30 PSI | 40 PSI | 50 PSI | 60 PSI | 70 PSI | 80 PSI | 90 PSI | 100 PSI |

| 1/16″ | .0625″ | 2 | 2.5 | 3.1 | 3.7 | 4.2 | 4.8 | 5.4 | 5.9 | 6.5 |

| 3/32″ | .09375” | 4.4 | 5.7 | 7 | 8.2 | 9.5 | 10.8 | 12.1 | 13.3 | 14.6 |

| 1/8″ (#2) | .125″ | 7.9 | 8.38 | 10.29 | 12.2 | 14.02 | 15.93 | 17.76 | 19.67 | 21.8 |

| 3/16” (#3) | .1875” | 15 | 18.92 | 23.24 | 27.39 | 31.54 | 35.85 | 40.08 | 44.15 | 49 |

| 1/4″ (#4) | .25” | 26 | 33.62 | 41.17 | 48.64 | 56.11 | 63.66 | 71.13 | 78.68 | 85 |

| 5/16” (#5) | .3125” | 42 | 54.61 | 67.07 | 79.1 | 91.13 | 103.63 | 115.66 | 127.74 | 140 |

| 3/8” (#6) | .375” | 58 | 75.61 | 92.96 | 109.56 | 126.16 | 143.59 | 160.19 | 176.79 | 194 |

| 7/16″ (#7) | .4375” | 83 | 105.03 | 128.65 | 152.31 | 175.55 | 199.2 | 222.44 | 245.68 | 268 |

| 1/2″ (#8) | .5″ | 105 | 143.46 | 164.34 | 195.05 | 224.93 | 254.81 | 284.69 | 314.57 | 346 |

Other Sandblasting Conversion Charts

WARNING NOTICE!!!

The products and equipment sold by Raptor Blasting Systems are not under any circumstances to be used with sand or silica products of any type. Use of such materials in our abrasive blasting equipment will void any warranty. Also, as with the use of any product or equipment, you must be sure to use the proper safety equipment, and to properly train your employees in the use of any equipment or products. Raptor Blasting Systems assumes no responsibility arising from the failure to use proper safety equipment, or the failure to properly train employees in the use of products and equipment.

Never operate blast cabinets with doors open!