Here at Raptor Blaster, we use a BNP style blasting gun in all our blast cabinets. There are a ton of reasons we prefer this style of blast cabinet gun.

For one, this style of abrasive blasting gun is easy for the blast cabinet operator to use. Many down-market blast guns don’t provide a comfortable grip, which makes your hand tired after long periods of blasting. Other low-end blast guns are notorious for their difficulty in picking up media in a siphon blast setup. Cheaper blast guns are also know for uneven blast patterns.

We like using the BNP blasting cabinet gun because it provides a predictable and precise texture pattern on the blasted surface. This is important if you are removing burrs or other imperfections; stripping rust, paint, or contaminants; or preparing a surface for protective coating.

Additionally, the BNP style gun keeps the air jet and blast nozzle in alignment, which means less wear and tear, and increased blast efficacy.

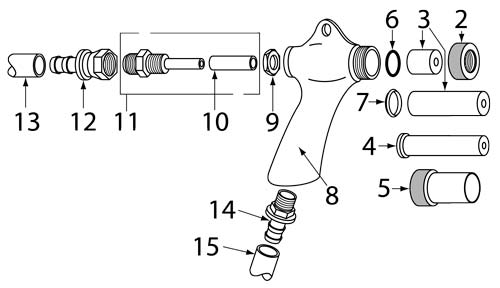

Another great feature is the knurled nut at the gun outlet. This allows the blast operator to change nozzles without additional tools. Where this comes in handy is if you need to switch the type of blast nozzle you are using for a specific application.

Ceramic blast nozzles are best for general type abrasive media, such as glass beads, plastic media, or organic blast media. Tungsten carbide nozzles can be used for harder abrasives such as garnet. Boron carbide blast nozzles are a good choice for the most aggressive types of blast media – like silicon carbide, steel grit or steel shot.

One additional advantage of the BNP style gun is the ability to use special extension or angled tip nozzles in specific applications.

Remember, if you need replacement parts for your Raptor Blaster cabinet, or simply want advice on what accessories to order, you can send us a quote request or call us at (916) 409-2458.